Redefining the Future of Precision Manufacturing

Built on the foundation of ultimate precision, we transcend the boundaries of traditional manufacturing.

Powered by continuous innovation, we conquer the industry's greatest challenges.

Enabled by intelligent manufacturing, we've created the first 24/7 unmanned factory for aero-engine turbine blades.

With fully proprietary core technologies and our original "Three Algorithms" system,

Pegasus is committed to delivering world-class digital precision manufacturing solutions

to the global aerospace and energy industries, pioneering a new era of intelligent manufacturing.

Efficiency

Precision

Innovation

World-Class Manufacturing

Capabilities Proven

by Numbers

traditional methods

Products & Services

Full-chain precision manufacturing services for turbine blades

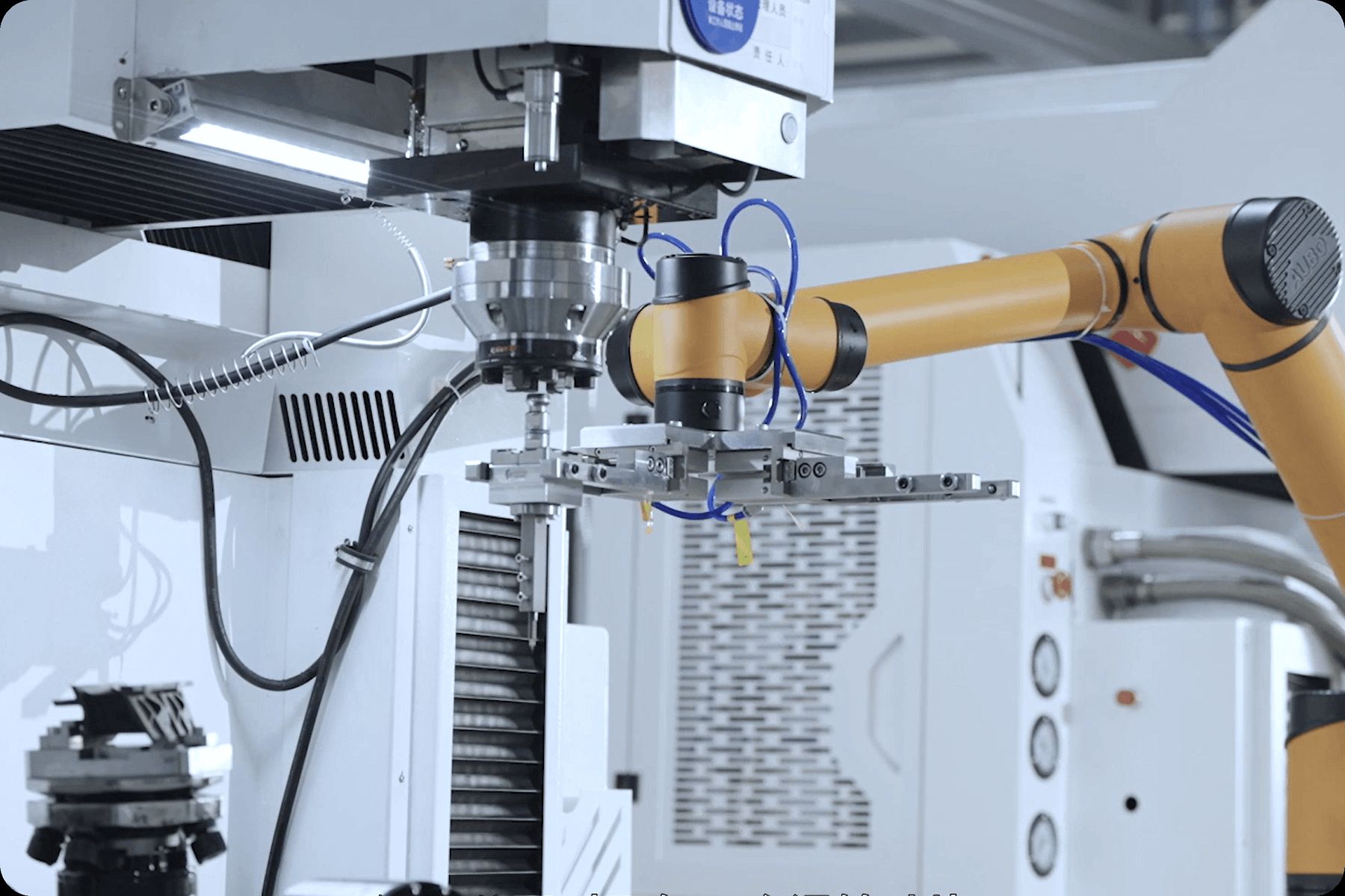

24/7 Unmanned Factory

Core Technologies & Processes

Setting New Standards in Digital Manufacturing

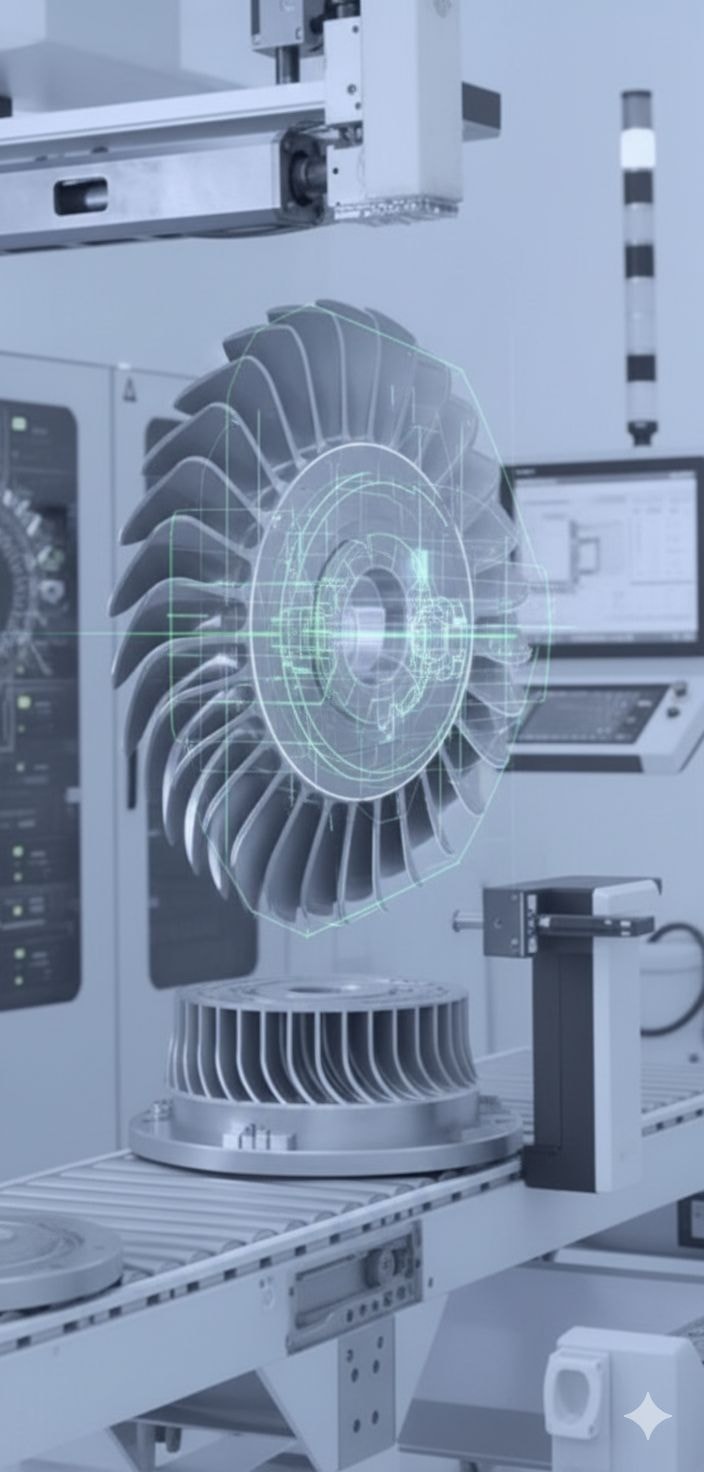

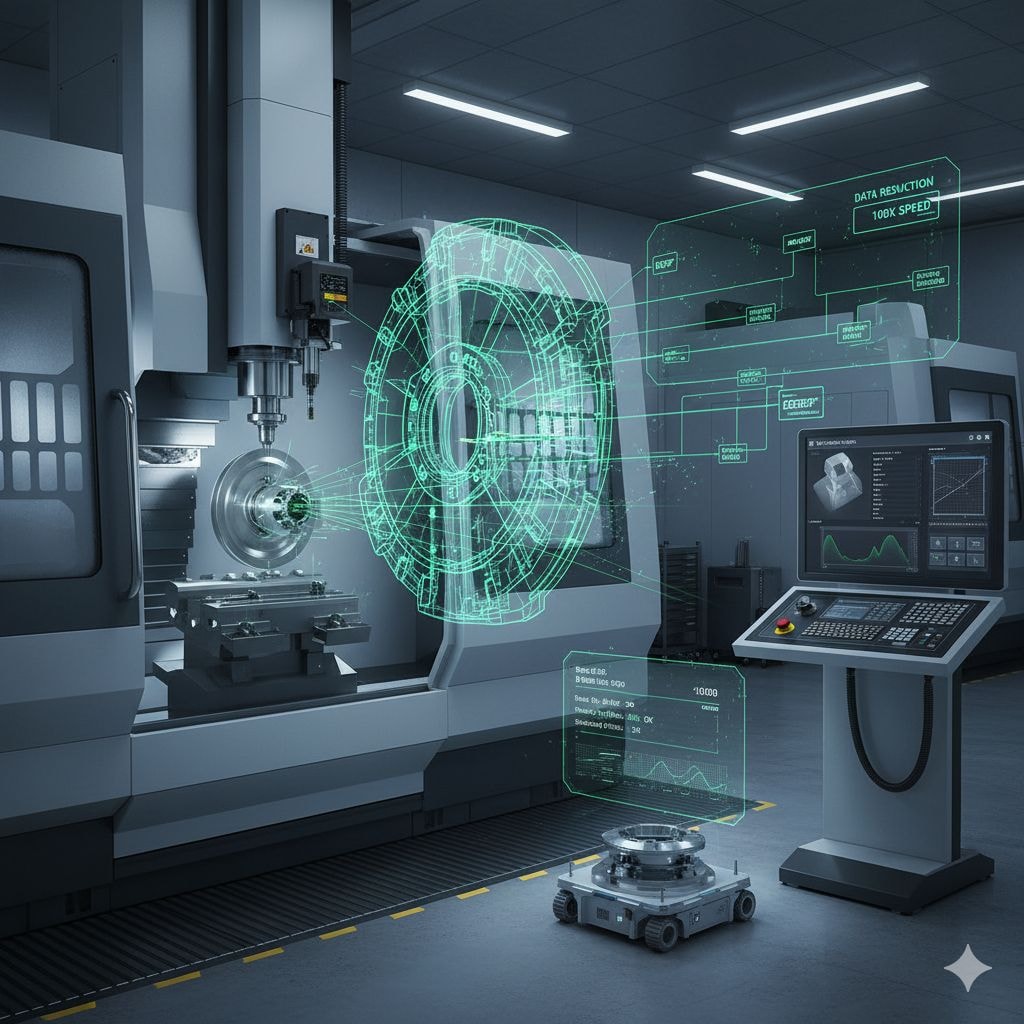

Digitalization

- 3D precision modeling and measurement systems

- Full-process virtual simulation and verification

- Seamless connection between design and manufacturing

- 99% CAD data reduction, 100x faster simulation

Key Achievements

- Virtual design directly drives physical assembly — a world first

- Millions in testing costs saved

- Each blade features an independent digital twin profile

Visualization

Three proprietary algorithms solving world-class challenges:

- Compensates for precision casting tolerances

- Ensures consistency across every blade

- Establishes unified digital machining datum

- Eliminates cumulative errors

- Optimizes complex spatial toolpaths

- AI-driven coordinate system establishment

Key Achievements

- Rework rate < 0.01%

- Zero manual intervention

- Micron-level machining accuracy

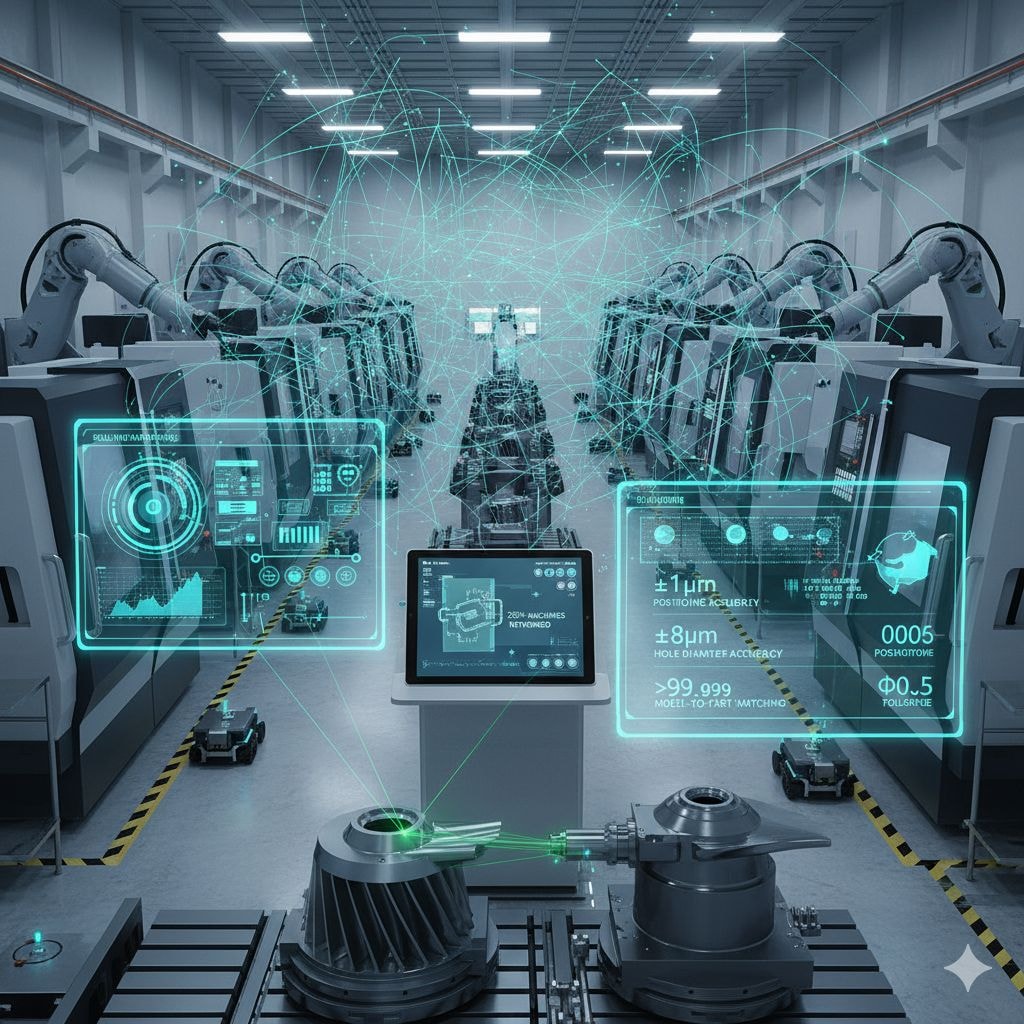

Automation

- 200+ in-house developed machines networked

- Industrial software drives full automation

- Real-time monitoring and predictive maintenance

- Cloud-based parameter synchronization

Key Achievements

- ±1μm Positioning Accuracy

- ±8μm Hole Diameter Accuracy

- ±12μm Hole Position Accuracy

- >99.99% Model-to-Part Matching

- Φ0.05 Positional Tolerance